Voltage Sag or Voltage Dip (IEC term) is defined by the IEEE 1159 as the decrease in the RMS voltage level to 10% - 90% (1% - 90% for EN 50160) of nominal, at the power frequency for durations of ½ cycle to one (1) minute. Also, voltage sag is classified as a short duration voltage variation phenomena, which is one of the general categories of power quality problems.

Voltage sag (dip) durations are subdivided into three categories: instantaneous (½ cycle to 30 cycles), momentary (30 cycles to 3 seconds), and temporary (3 seconds to 1 minute). These durations are intended to correlate with typical protective device operation times as well as duration divisions recommended by international technical organizations. Sags are widely recognized as among the most common and important aspects of power quality problems affecting commercial and industrial customers - they are virtually unnoticeable by observing lighting blinks but many industrial processes would have shutdown. Possible effects of voltage sags would be system shutdown or reduce efficiency and life span of electrical equipment, specifically motors. Therefore, such disturbances are particularly problematic for industry where the malfunction of a device may result in huge financial losses.

Voltage Sag (Dip) Terminology Usage

The term voltage sag has been used in the power quality community for many years to describe a specific type of power quality disturbance - a short duration voltage decrease. The IEC definition for this phenomenon is voltage dip. The two terms are considered to be interchangeable. Generally, sag is preferred in the US and dip is common in European countries.

Terminology used to describe the magnitude of voltage sag is often confusing. According to IEEE 1159-1995, the recommended usage is “a sag to 65%”, which means that the line voltage is reduced down to 65% of the normal value, not reduced by 65%. Using the preposition “of” (as in “a sag of 65%”, or implied in “a 65% sag”) is deprecated. This preference is consistent with IEC practice, and with most disturbance analyzers that also report remaining voltage. Just as an unspecified voltage designation is accepted to mean line-to-line potential, so an unspecified sag magnitude will refer to the remaining voltage. Where possible, the nominal or base voltage and the remaining voltage should be specified.

Voltage sags are generally caused by weather and utility equipment problems, which normally lead to system faults on the transmission or distribution system. For example, a fault on a parallel feeder circuit will result in a voltage drop at the substation bus that affects all of the other feeders until the fault is cleared. The same concept would apply for a fault somewhere on the transmission system. Most of the faults on the utility transmission and distribution system are single-line-to-ground (SLG) faults.

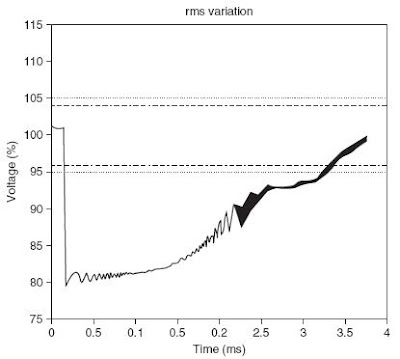

Voltage sags can also be caused by the switching of heavy loads or the starting of large motors. To illustrate, an induction motor can draw six to ten times of its full load current during starting. If the current magnitude is relatively larger than the available fault current at that point in the system, the voltage sag can become significant.

|

| Voltage Sag Caused By Motor Starting |

|

| Approaches For Voltage Sag Ride-Through |

1. Incorporate voltage sag ride-through capability into the equipment. This is generally the less costly and best solution. Tips on ensuring voltage sag ride-through are as follows:

Ø Equipment manufacturers should have voltage sag ride-through capability curves available to their customers, who should begin to demand these types of curves to be made available so that they can properly evaluate the equipment.

Ø The company procuring new equipment should establish a procedure that rates the importance of the equipment. If the equipment is critical in nature, the company must make sure that adequate ride-through capability is included when the equipment is purchased.

Ø Equipment should at least be able to ride through voltage sags with a minimum voltage of 70 percent (ITIC curve). A more ideal ride-through capability for short-duration voltage sags would be 50 percent, as specified by the semiconductor industry in SEMI F-47.

2. Apply an uninterruptible power supply (UPS) system or some other type of power conditioning to the machine control. This is applicable when the machines themselves can withstand the sag or interruption, but the controls would automatically shut them down.

3. Backup power supply with the capability to support the load for a brief period.

4. Utility power system improvements to significantly reduce the number of sags and interruptions (e.g. replacement of relays).

Synopsis:

Magnitude: 0.1 to 0.9 pu

Source: Utility or large load start by end-users

Duration: ½ cycle to 1 minute

Symptoms: Malfunction or Shutdown

Occurrence: Average of 50 events/year in the US

Mitigating Devices: Constant Voltage Transformers (CVT), Uninterruptible Power Supply (UPS), Dynamic Voltage Restorer (DVR)

References:

Bollen, M. (2000). Understanding Power Quality Problems: Voltage Sags and Interruptions.

Dugan, R., McGranaghan, M., Santoso, S., and Beaty, H.W. (2004). Electrical Power Systems Quality (2nd ed.). New York: McGraw-Hill.

IEEE 1159-1995. Recommended Practice For Monitoring Electric Power Quality.

Leng, O.S. (2001). Simulating Power Quality Problems

No comments:

Post a Comment